The chili paste grinder provided by Taizy is the most critical step in chili sauce production. To achieve smooth, even, and brightly colored chili paste, the grinder fully refines chili raw materials through high-speed shearing, pressing, impact, and emulsification. Below, we explain in detail how the Chili Paste Grinder works, from structure and operating mechanism to processing flow and advantages.

Main Structure of the Chili Paste Grinder

The chili paste grinder’s main structure includes the rotor and stator, feeding system, cooling system, and discharge system.

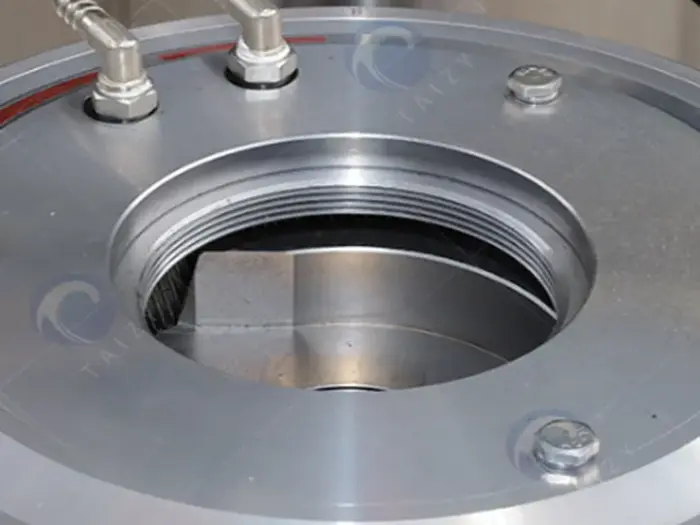

Stator and Rotor – Core Grinding Components

The rotor spins at high speed while the stator stays still, creating a very fine grinding gap. Chili is repeatedly sheared and pressed here, gradually turning into a smooth paste.

Feeding System

Pre-treated chili is continuously and steadily delivered to the grinding chamber, ensuring even grinding.

Cooling System – Water Circulation

The heat generated during grinding can affect the color and spiciness of chili. A water-cooling system keeps the temperature suitable, improving the quality of the chili paste.

Discharge System

The ground chili paste flows out from the discharge outlet and can go directly to the next steps, such as seasoning, sterilization, or filling.

Working Principle of the Chili Paste Grinder

The chili paste grinding machine works by high-speed rotation between the stator and rotor, creating strong shearing, pressing, and friction forces that quickly break down and refine the chili. As chili enters the grinding chamber, it is repeatedly pressed into smaller particles under high-speed shearing, while moisture and oil fully mix and emulsify. This produces smooth, even, and fine chili paste. The process is continuous and efficient, and the grind size can be adjusted by changing the grinding gap.

Processing Flow of Chili Paste

Using a chili paste grinding machine to make chili paste usually involves the following main steps, each directly affecting the taste, color, and stability of the final product:

Raw Material Selection and Cleaning

- Choose mature, bright red, and mold-free chili. Clean to remove dirt and impurities.

Deseeding, Cutting, or Rough Crushing

- Depending on the product, remove seeds and cut or roughly crush chili to prepare for grinding.

Pre-cooking or Color Protection

- Some factories heat chili briefly or add color-protecting agents to maintain bright red color.

Grinding into Paste

- Use the Chili Paste Grinder or colloid mill to process chili into a smooth paste. This is the core step. Grind size usually reaches 50–200 mesh and can be adjusted according to factory needs.

Seasoning and Mixing

- Add salt, oil, garlic, ginger, sugar, spices, and other ingredients. Mix thoroughly with the chili paste.

High-Temperature Sterilization

- Heat in a jacketed kettle or sterilizer to extend shelf life and ensure food safety.

Vacuum Degassing

- Remove air from the paste to improve stability and filling quality.

Filling and Sealing

- Use a sauce filling machine for measured filling, then seal.

Cooling, Labeling, and Packaging

- After cooling, label and package the chili paste for shipment.

Recommended Technical Parameters of Taizy Chili Paste Grinder

| Model | Voltage (V) | Power (KW) | Capacity (KG/h) | Weight (KG) | Dimensions (mm) |

|---|---|---|---|---|---|

| GN-50 | 380/50HZ | 1.5 | 10–30 | 65 | 610×400×700 |

| GN-80 | 380/50HZ | 4 | 50–100 | 170 | 850×450×930 |

| GN-110 | 380/50HZ | 7.5 | 100–200 | 220 | 850×450×1050 |

| GN-130 | 380/50HZ | 11 | 200–300 | 350 | 1000×500×1100 |

| GN-180 | 380/50HZ | 18.5 | 500–800 | 440 | 1050×550×1100 |

| GN-220 | 380/50HZ | 30 | 600–900 | 580 | 1080×600×1350 |

| GN-240 | 380/50HZ | 37/45 | 1000–1500 | 800 | 1400×600×1350 |

| GN-300 | 380/50HZ | 75/90 | 3000–5000 | 1200 | 1500×700×1450 |

Core Advantages of the Chili Paste Grinder

High Grinding Fineness

The finished chili paste has uniform particles and a smooth texture. Grinding fineness usually reaches 50–200 mesh. The stator and rotor rotate at high speed, typically 2800–4500 rpm, enabling ultra-fine grinding quickly.

Continuous, Efficient, and Stable Production

Supports uninterrupted feeding and discharge. Single-machine output ranges from 100–2000 kg/h, depending on the model, ideal for medium and large-scale food factories, boosting overall productivity.

Low Heat Rise, Maintains Color and Spiciness

Equipped with a water-cooling system to keep the grinding temperature ≤45°C, preventing chili from discoloring, darkening, or losing spiciness, ensuring stable product quality.

Multi-purpose, Wide Material Compatibility

Not only suitable for chili, but also various sauce-type materials, including:

- Chili

- Peanut paste

- Sesame paste

- Tomato

- Garlic, ginger

- Fruit purees, nut pastes, and more

Cooperate with Taizy

By choosing to cooperate with Taizy, you benefit from over 20 years of professional experience in food machinery manufacturing, high-quality chili grinding and seasoning production equipment, customized production line solutions, and full-process after-sales support. This chili paste grinder is not only suitable for chili paste but also processes peanut paste, sesame paste, tomato paste, garlic, ginger, and various fruit purees, enabling efficient, stable, and multi-product production.