The industrial continuous vegetable blanching machine is a blanching device in the color protection process of fruit and vegetable processing. This equipment integrates blanching and cooling. It has the characteristics of rapid deactivation, enzyme inhibition, color protection, and dehydration and cooling.

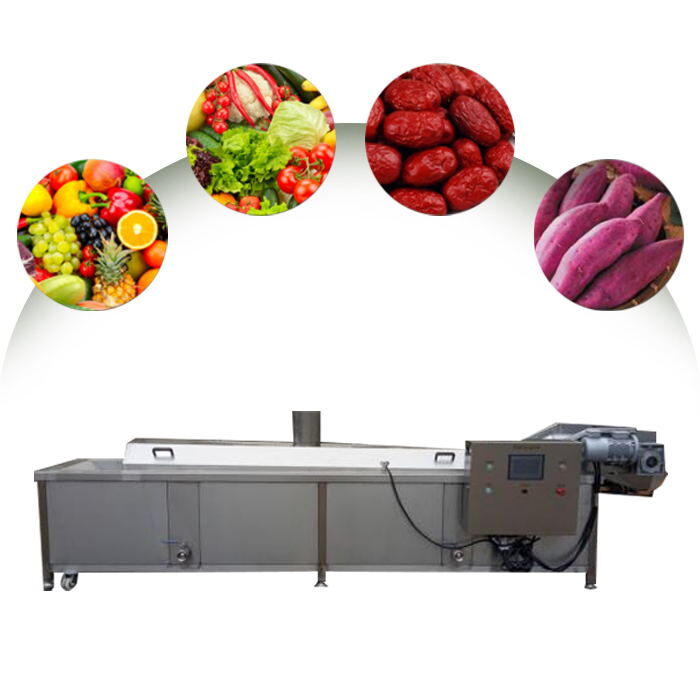

The vegetable cooking blanching machine can be used for cooking and blanching of fruit, root vegetables, fruit slices, etc., and can also be used for blanching meat-packed products.

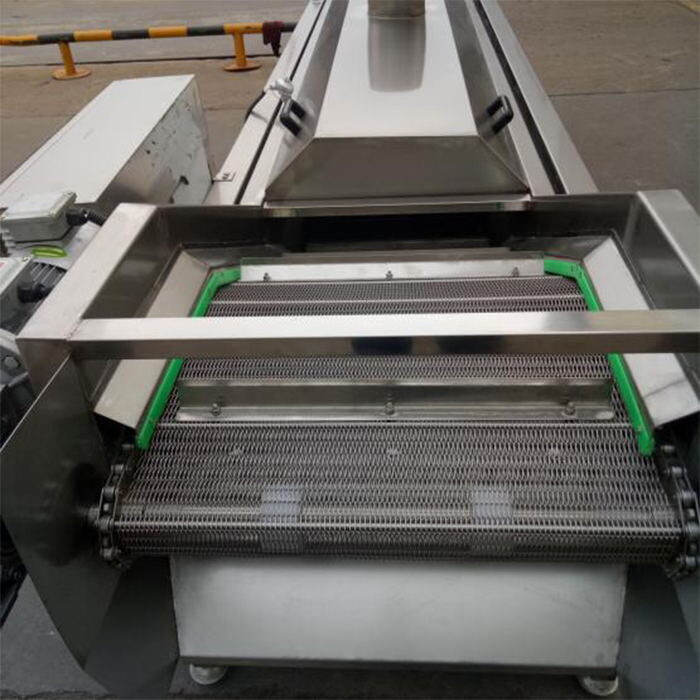

The whole machine is made of full 304 stainless steel with a double-layer mesh belt. The output can reach 900 kg/h. The heating method can be boiler steam, boiler hot water, or electric heating. It is easy to operate with a low failure rate.

This fruit blanching sterilizer has been widely exported to more than 20 countries and regions, including Germany, Spain, and Bolivia, and has received great acclaim from customers.

Application Areas

The blanching machine is mainly used for blanching and enzyme inactivation of fruits, root vegetables, carrots, asparagus, mushrooms, fruit slices, seafood, corn, and other products. It is an essential pre-treatment equipment for processes such as quick freezing, dehydration, and freeze-drying.

Functions of the Vegetable Blanching Machine

The vegetable blanching machine is suitable for cooking and blanching fruits, vegetables, and aquatic products. It is an essential pre-treatment equipment for processes such as quick freezing, dehydration, and freeze-drying.

The machine features rapid enzyme inactivation and color protection, timely dehydration and cooling, effectively inhibiting enzyme activity in fruits and vegetables, preserving their fresh color and natural flavor, removing raw odors, enhancing cell softness, and promoting moisture evaporation, thus providing strong support for subsequent dehydration processing.

- Rapid enzyme inactivation and color protection: Effectively inhibits enzyme activity in fruits and vegetables, maintaining bright color.

- Odor removal: Eliminates raw or grassy flavors, improving taste and aroma.

- Pre-sterilization treatment: Reduces microbial content and extends product shelf life.

- Improved texture: Enhances cell softness, making subsequent dehydration, freezing, or drying more efficient.

- Cooling and dehydration link: Rapid cooling after blanching minimizes nutrient loss and ensures better preparation for further processing.

Working principle of the vegetable cooking blanching machine

The blanching equipment consists of two parts: a blanching machine and a cooling machine.

During operation, water is added to the blanching machine through the inlet and heated. The products to be processed are then conveyed into the machine, where the blanching time and temperature are set according to process requirements to complete blanching and enzyme deactivation. Afterwards, the products automatically enter the cooling machine for rapid cooling, effectively preserving and enhancing color while extending the shelf life of the food.

Structure of the vegetable blanching machine

Heating system

Steam, electric heating, or hot water heating for rapid temperature rise.

Water injection system

Supplies water through the inlet to ensure even blanching.

Conveying system

Conveyor belt or chain system to evenly transport vegetables into the blanching zone.

Control system

Adjustable temperature and time to ensure consistent blanching results.

Discharge and cooling interface

After blanching, products can be automatically conveyed to the cooling machine.

Technical parameters

| Parameter | Specification |

|---|---|

| Customizable | Yes |

| Item Number | 25 |

| Type | Pre-cooking Machine |

| Brand | Tziay |

| Model | TZ-900 |

| Production Capacity | 900Kg/h |

| Power | 5 kW |

| Voltage | 380 V |

| Dimensions | 6000 mm |

| Application | Blanching, washing, and air-drying |

| Net Weight | 5000 kg |

| Packaging | Stretch film |

| Cross-border Export Exclusive | No |

If you need a blanching machine with higher capacity, please contact us for consultation. Wheels, material, voltage, plug type, mesh belt density, and other specifications can all be customized.

How to blanch vegetables?

Water injection and heating

Add water to the blanching machine through the inlet and start the heating system to bring the water to the required temperature.

Loading and blanching

Place cleaned vegetables evenly onto the conveyor belt or hopper, which automatically transports them into the blanching machine for hot water blanching.

Time and temperature control

Set the appropriate blanching time and temperature according to the type of vegetable and processing requirements to achieve enzyme inactivation, color protection, and flavor retention.

Automatic discharge

After blanching, the vegetables are automatically conveyed out of the machine and sent to the next step—the cooling machine.

Cooling and shaping

Vegetables are rapidly cooled in the cooling machine, preserving color and shape while slowing down the oxidation process.

Features of vegetable boiling blanching machine

1. The whole machine adopts high-quality SUS304 stainless steel, with water as the medium, divided into two parts: the bleaching tank and the cooling tank. The blanching temperature and speed can be set according to the requirements of material processing technology.

2. The industrial vegetable and fruit blanching and sterilizing machine is a new product that absorbs foreign advanced technology and combines the current production technology of domestic food, beverage, pharmaceutical, and other industries to successfully develop a new product integrating sterilization, blanching, cooling, and other functions.

3. Completely solve the “randomness” caused by the low degree of automation in the blanching process, strengthen the “consistency”, and greatly improve the success rate of blanching and finishing.

4. The equipment is also suitable for the marinating and maturation of poultry eggs, meat, fish, shells, etc., as well as the sterilization of canned food such as pickles, fruits, and fungi.

5. The water temperature is automatically controlled by the temperature controller and can be set at will. The heat source can be steam heating, electric heating, etc., and the speed can be adjusted by frequency conversion. The double-layer insulation material is currently the most advanced food and vegetable blanching equipment in China.

6. The industrial continuous vegetable blanching machine can realize standardization and continuous operation, and enhance the processing strength and overall image of the enterprise.

7. The equipment has a compact structure and a high degree of automation, which is suitable for enterprises of various processing scales.

8. Short investment recovery time and high productivity can replace a large number of manual operations, reducing labor costs and labor intensity for enterprises.

vegetable blanching machine production line

The blanching machine production line consists of a blanching machine, a cooling machine, and a conveying system. It is suitable for the heat treatment of fruits, vegetables, and aquatic products. We can also provide a complete production line solution.

In addition, we also offer a range of machines, including bubble washing machines and vegetable air-drying machines. Welcome to contact us for more information.