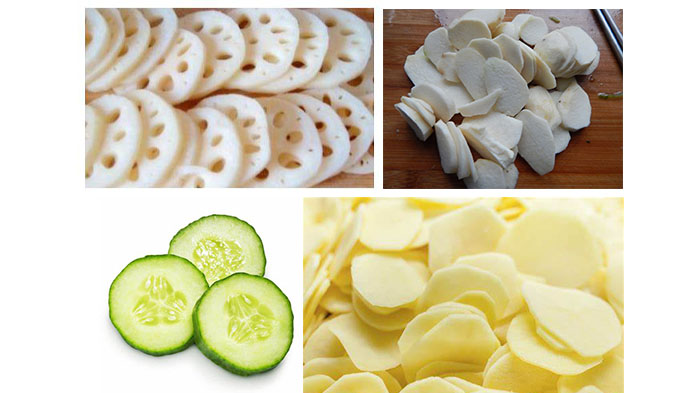

เครื่องตัดกระเทียมเป็นเครื่องตัดอเนกประสงค์หรือเรียกอีกอย่างว่าเครื่องตัดขิง นอกจากนี้ยังสามารถนำไปใช้กับมันฝรั่ง รากบัว แอปเปิ้ล ลูกแพร์ หัวไชเท้า แตงกวา เผือกฝาน และก้านและรากผลไม้และผักชิ้นอื่นๆ ฝานกระเทียมที่ตัดด้วยเครื่องตัดกระเทียมนี้มีรูปร่างที่เรียบร้อยและมีความหนา เป็นเครื่องหั่นที่เหมาะสำหรับอุตสาหกรรมแปรรูปอาหาร หน้าอาหารแช่แข็ง สถานประกอบการแปรรูปผัก ฯลฯ

การใช้เครื่องตัดกระเทียมเชิงพาณิชย์

ประสิทธิภาพในการสไลซ์ของเครื่องสไลซ์กระเทียมเชิงพาณิชย์นั้นสูงมาก ซึ่งสูงกว่าการทำด้วยมือหลายสิบเท่า สามารถใช้แปรรูปกระเทียมฝาน ขิงฝาน มันฝรั่งฝาน เผือกฝาน มันเทศฝาน และผลิตภัณฑ์อื่นๆ ชิ้นผักที่หั่นมีความหนาสม่ำเสมอ ขนาดเท่ากัน และเนื้อเยื่อพื้นผิวที่ตัดสดใหม่และไม่ทำลายเนื้อเยื่อเส้นใย นอกจากนี้ เรายังมีเครื่องจักรแปรรูปกระเทียมอื่นๆ เช่น เครื่องตัดรากกระเทียม เครื่องปอกเปลือกกระเทียม เครื่องอบแห้งกระเทียม เป็นต้น

ความต้องการวัตถุดิบสำหรับเครื่องหั่นกระเทียม

แม้ว่าเครื่องตัดกระเทียมนี้สามารถตัดวัสดุได้หลายประเภท แต่ก็มีข้อกำหนดด้านความชื้นของวัสดุแปรรูป

- วัสดุเปียกจะตัดได้ง่ายกว่าวัสดุแห้ง หากใช้เครื่องตัดกระเทียมเพื่อตัดวัสดุที่แห้งเกินไป อาจตัดวัสดุให้เป็นผงได้

- วัสดุที่มีความหนืดสูงสามารถเพิ่มความหนาของเครื่องตัดได้

ขั้นตอนการทำงานของเครื่องตัดกระเทียมขิง

- การป้อน: หลังจากเปิดเครื่องแล้ว ให้ใส่วัสดุลงในช่องป้อน (อย่างต่อเนื่องอย่างต่อเนื่อง)

- การหั่น: วัสดุสัมผัสกับวัสดุ และวัสดุถูกตัดเป็นชิ้นด้วยแรงเหวี่ยง ซึ่งสามารถหั่นได้อย่างต่อเนื่อง

- การระบาย: วัสดุถูกระบายออกจากช่องระบาย

ทักษะการทำงานของเครื่องตัดกระเทียมขิง

สามารถป้อนวัสดุได้อย่างต่อเนื่องและวัสดุถูกบีบเข้าหากัน (อุปกรณ์ใช้หลักการแรงเหวี่ยง) และผลการหั่นจะดีกว่า

วัสดุขนาดใหญ่สามารถหล่อลื่นด้วยน้ำเพื่อป้องกันการแตกหักของเศษ (อุปกรณ์มีช่องเติมน้ำ)

เมื่อวัสดุถูกปล่อยลงน้ำ วัสดุสามารถรักษาสภาพเดิมได้ และสามารถปกป้องสีเดิมของวัสดุได้ดีขึ้น

วิธีใช้เครื่องหั่นกระเทียมขิง

- เมื่อปรับเครื่องตัดกระเทียม ให้คลายและขันน็อตคอลัมน์ทองแดงให้แน่นก่อน จากนั้นหมุนน็อตและทิศทางความหนาของคอลัมน์ทองแดงเพื่อปรับ หลังจากปรับความหนาแล้ว ต้องขันน็อตและเสาทองแดงให้แน่น หากหัวตัดขนานกับใบมีด ห้ามเปิดเครื่อง หัวตัดจะต้องอยู่ต่ำกว่าใบมีดก่อนจึงจะสามารถตัดเครื่องตัดได้ การปรับที่หนาที่สุดคือประมาณ 3 มม. และสามารถปรับทินเนอร์ได้แบบไม่มีขั้นตอน

- ใส่ด้ามจับหกเหลี่ยมเข้าไปในรูด้านข้างตัวเครื่อง หมุนทิศทางของล้อเพื่อเปลี่ยนมีด เมื่อเปลี่ยนมีด ให้คลายสกรูหกเหลี่ยมสองตัวของใบมีดแล้วใส่ใบมีดเพื่อเปลี่ยน

ข้อควรระวังในการใช้เครื่องตัดกระเทียม

- อ่างมีดมักจะถูด้วยน้ำมันเพื่อไม่ให้สิ่งสกปรกเกาะติด หากหางเม็ดยาและเศษเล็กๆ ปรากฏขึ้น แสดงว่าการอ่อนตัวไม่เหมาะสมหรือใบมีดไม่คม และต้องเปลี่ยนหรือลับมีดใหม่ มันบางเกินไปที่จะตัด

- หั่นยาที่มีความหนืด เช่น Tianyun, Shengdi, Yuanshen และ Gastrodia elata แล้วหั่นด้วยน้ำบนพื้นผิว

พารามิเตอร์เครื่องตัดขิงชนิดขายร้อน

แรงดันไฟฟ้า: 110-220-380V

กำลังไฟฟ้า: 1500W

ขนาด: 970*700*1040ซม. 150กก

เอาท์พุต: 500กก./ชม