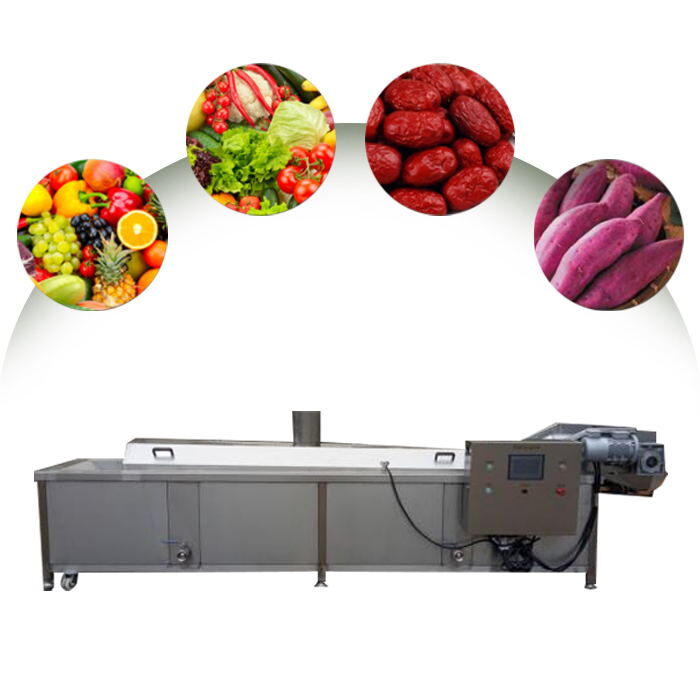

Mashine ya kuchemsha mboga ya viwandani ni kifaa cha kuchemsha katika mchakato wa ulinzi wa rangi wa usindikaji wa matunda na mboga. Vifaa hivi vinajumuisha kuchemsha na kupoeza. Ina sifa za kuondoa haraka, kuzuia enzymes, kulinda rangi, na kuondoa unyevu na kupoza.

Mashine ya kuchemsha mboga inaweza kutumika kwa kupika na kuchemsha matunda, mboga za mizizi, vipande vya matunda, n.k., na pia inaweza kutumika kwa kuchemsha bidhaa za nyama zilizofungashwa.

Mashine nzima imetengenezwa kwa chuma cha pua 304 chenye mesh belt ya tabaka mbili. Utoaji unaweza kufikia 900 kg/h. Njia ya kupasha joto inaweza kuwa moshi wa boiler, maji moto ya boiler, au joto la umeme. Ni rahisi kutumia na kiwango cha chini cha kushindwa.

Sterilizer hii ya kuchemsha matunda imesafirishwa kwa wingi katika nchi na maeneo zaidi ya 20, ikiwa ni pamoja na Ujerumani, Uhispania, na Bolivia, na imepokelewa kwa sifa kubwa kutoka kwa wateja.

Mikoa ya Maombi

Mashine ya kuchemsha inatumiwa hasa kwa ajili ya kuchemsha na kuondoa enzymes za matunda, mboga za mizizi, karoti, asparagus, uyoga, vipande vya matunda, samaki, mahindi, na bidhaa nyingine. Ni kifaa muhimu cha kabla ya matibabu kwa michakato kama vile kufungia haraka, kuondoa unyevu, na kukausha kwa barafu.

Kazi za Mashine ya Kuchemsha Mboga

Mashine ya kuchemsha mboga inafaa kwa kupika na kuchemsha matunda, mboga, na bidhaa za majini. Ni kifaa muhimu cha kabla ya matibabu kwa michakato kama vile kufungia haraka, kuondoa unyevu, na kukausha kwa barafu.

Mashine ina sifa za kuondoa haraka enzyme na kulinda rangi, kuondoa unyevu kwa wakati, na kupoza, ikizuia kwa ufanisi shughuli za enzyme katika matunda na mboga, ikihifadhi rangi zao safi na ladha ya asili, kuondoa harufu mbovu, kuimarisha unyevu wa seli, na kukuza uvukizi wa unyevu, hivyo kutoa msaada mzito kwa mchakato wa kuondoa unyevu.

- Kuzima kwa haraka kwa enzymes na ulinzi wa rangi: Inazuia kwa ufanisi shughuli za enzymes kwenye matunda na mboga, kudumisha rangi angavu.

- Uondoaji wa harufu: Inafuta ladha mbichi au ya majani, kuboresha ladha na harufu.

- Matibabu ya kabla ya kuua kuvuja: Inapunguza idadi ya vijidudu na kuongeza muda wa matumizi wa bidhaa.

- Muundo ulioboreshwa: Inaongeza upole wa seli, kufanya ukame unaofuata, baridi, au ukame kuwa na ufanisi zaidi.

- Uunganisho wa baridi na ukame: Baridi ya haraka baada ya kuchemsha inapunguza upotevu wa virutubisho na kuhakikisha maandalizi bora kwa usindikaji zaidi.

Kanuni ya kazi ya mashine ya kuchemsha mboga

Vifaa vya kuchemsha vinajumuisha sehemu mbili: mashine ya kuchemsha na mashine ya kupozea.

Wakati wa operesheni, maji yanaongezwa kwenye mashine ya kuchemsha kupitia inlet na yanapashwa moto. Bidhaa zinazopaswa kusindikwa kisha zinahamishwa ndani ya mashine, ambapo muda wa kuchemsha na joto huwekwa kulingana na mahitaji ya mchakato ili kukamilisha kuchemsha na kuondoa enzymes. Baada ya hapo, bidhaa zinaingia moja kwa moja kwenye mashine ya kupoza kwa ajili ya kupoza haraka, ikihifadhi na kuimarisha rangi huku ikiongeza muda wa kuhifadhi chakula.

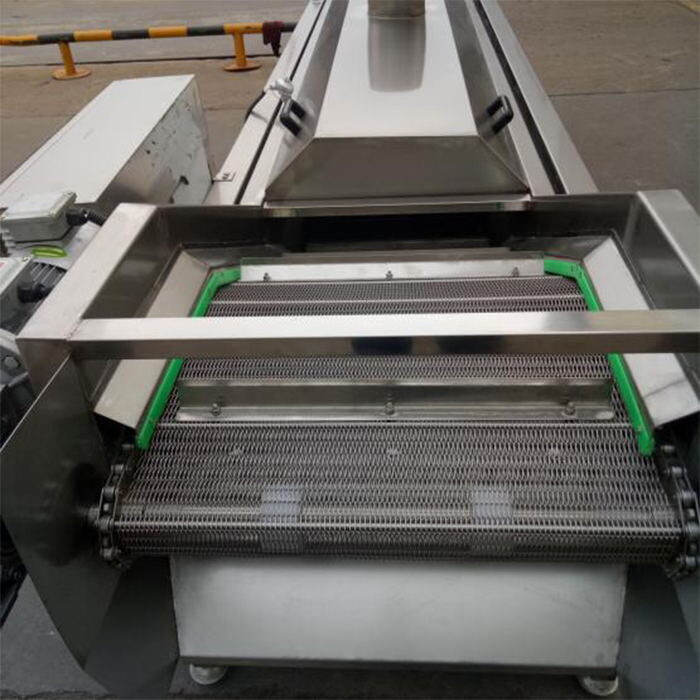

Muundo wa mashine ya kuchemsha mboga

Mfumo wa kupasha joto

Moshi, joto la umeme, au joto la maji moto kwa ajili ya kuongezeka kwa haraka kwa joto.

Mfumo wa kuingiza maji

Inatoa maji kupitia inlet ili kuhakikisha kuchemsha kwa usawa.

Mfumo wa usafirishaji

Mfumo wa mnyororo au belt ya usafirishaji ili kusafirisha mboga kwa usawa ndani ya eneo la kuchemsha.

Mfumo wa kudhibiti

Joto na muda vinavyoweza kubadilishwa ili kuhakikisha matokeo ya kuchemsha yanayofanana.

Kiunganishi cha kutolewa na kupoza

Baada ya kuchemsha, bidhaa zinaweza kuhamishwa moja kwa moja kwenye mashine ya kupoza.

Paramita za kiufundi

| Kigezo | Vipimo |

|---|---|

| Inayoweza kubadilishwa | Ndio |

| Nambari ya Kifaa | 25 |

| Aina | Mashine ya Kwanza ya Kupika |

| Brand | Tziay |

| Mfano | TZ-900 |

| Uwezo wa Uzalishaji | 900Kg/h |

| Nguvu | 5 kW |

| Voltage | 380 V |

| Vipimo | 6000 mm |

| Maombi | Kuchemsha, kuosha, na kukausha hewa |

| Uzito wa Net | 5000 kg |

| Ufungaji | Filamu ya kunyoosha |

| Uuzaji wa Mipaka | Hapana |

Ikiwa unahitaji mashine ya kuchemsha yenye uwezo mkubwa, tafadhali wasiliana nasi kwa ushauri. Magurudumu, nyenzo, voltage, aina ya plug, unene wa mesh belt, na vipimo vingine vinaweza kubadilishwa.

Jinsi ya blanch mboga?

Uingizaji wa maji na kupasha moto

Ongeza maji kwenye mashine ya kuchemsha kupitia inlet na uanzishe mfumo wa kupasha joto ili kuleta maji kwenye joto linalohitajika.

Kuweka na kuchemsha

Weka mboga safi kwa usawa kwenye mesh belt au hopper, ambayo inazisafirisha moja kwa moja kwenye mashine ya kuchemsha kwa ajili ya kuchemsha kwa maji moto.

Udhibiti wa muda na joto

Weka muda na joto linalofaa kulingana na aina ya mboga na mahitaji ya usindikaji ili kufikia uanzishaji wa enzyme, ulinzi wa rangi, na uhifadhi wa ladha.

Kutolewa kwa moja kwa moja

Baada ya kuchemsha, mboga zinawekwa moja kwa moja nje ya mashine na kutumwa hatua inayofuata—mashine ya kupoza.

Kupoeza na kutengeneza

Mboga zinapozwa kwa haraka kwenye mashine ya kupozea, zikihifadhi rangi na umbo wakati zinapopunguza mchakato wa oksidishaji.

Vipengele vya mashine ya kuchemsha mboga

1. Mashine nzima inatumia chuma cha pua cha SUS304, ikiwa na maji kama njia, ikigawanywa katika sehemu mbili: tanki la kuchemsha na tanki la kupoza. Joto na kasi ya kuchemsha vinaweza kuwekwa kulingana na mahitaji ya teknolojia ya usindikaji wa nyenzo.

2. Mashine ya kuchemsha na kuanzisha mboga na matunda ya viwandani ni bidhaa mpya inayopokea teknolojia ya kigeni ya kisasa na kuunganisha teknolojia ya uzalishaji ya ndani katika tasnia ya chakula, vinywaji, dawa, na sekta nyingine ili kuendeleza kwa mafanikio bidhaa mpya inayojumuisha sterilization, kuchemsha, kupoza, na kazi nyingine.

3. Tatua kabisa "nasibu" inayosababishwa na kiwango cha chini cha automatisering katika mchakato wa blanching, kuimarisha "uthabiti", na kuboresha sana kiwango cha mafanikio ya blanching na kumaliza.

4. Vifaa hivi pia vinafaa kwa ajili ya kuandaa na kuimarisha mayai, nyama, samaki, ganda, n.k, pamoja na sterilization ya chakula kilichohifadhiwa kama vile pickles, matunda, na uyoga.

5. Joto la maji linadhibitiwa moja kwa moja na mtawala wa joto na linaweza kuweka kwa mapenzi. Chanzo cha joto kinaweza kuwa inapokanzwa kwa mvuke, inapokanzwa umeme, nk, na kasi inaweza kubadilishwa na ubadilishaji wa mzunguko. Nyenzo ya insulation ya safu mbili kwa sasa ndio kifaa cha hali ya juu zaidi cha kukausha chakula na mboga nchini Uchina.

6. Mashine ya kuendelea ya kukausha mboga ya viwandani inaweza kutambua viwango na uendeshaji endelevu, na kuongeza nguvu ya usindikaji na taswira ya jumla ya biashara.

7. Vifaa vina muundo wa compact na shahada ya juu ya automatisering, ambayo yanafaa kwa makampuni ya biashara ya mizani mbalimbali ya usindikaji.

8. Muda mfupi wa kurejesha uwekezaji na tija kubwa inaweza kuchukua nafasi ya idadi kubwa ya shughuli za mwongozo, kupunguza gharama za kazi na nguvu ya kazi kwa makampuni ya biashara.

mstari wa uzalishaji wa mashine ya kuchemsha mboga

Mstari wa uzalishaji wa mashine ya kuchemsha unajumuisha mashine ya kuchemsha, mashine ya kupozea, na mfumo wa usafirishaji. Unafaa kwa matibabu ya joto ya matunda, mboga, na bidhaa za majini. Tunaweza pia kutoa suluhisho kamili la mstari wa uzalishaji.

Mbali na hayo, pia tunatoa aina mbalimbali za mashine, ikiwa ni pamoja na mashine za kuosha bubble na mashine za kukausha mboga kwa hewa. Karibu kuwasiliana nasi kwa maelezo zaidi.