The combined chili paste grinding machine is developed on the basis of the peanut butter grinder. The machine can realize multi-pass grinding of chili. Similarly, the chili paste combination grinder is also suitable for grinding peanuts, sesame seeds, peppers, cocoa beans, and other products. Since it is ground through more than two combined mills, the peanut butter it grinds is more delicate than that of a single-pass grinder.

This chili paste grinding machine has a capacity range of 10–5000 kg/h, with a maximum daily output of up to 60 tons in 12 hours. It is suitable for large-scale chili paste production. The processed material can reach a fineness of 100–200 mesh, with particle sizes of 2–50 microns and a homogenization rate of over 90%. It is an ideal device for ultra-fine material processing.

This machine processes materials without contamination, meeting food safety standards in most countries. It is easy to operate and clean, and the fineness of the processed material can be adjusted.

If you are looking for a high-quality and cost-effective chili paste grinding machine, you can inquire about the price and more details using the pop-up on the right.

Characteristics

- The combined chili paste grinding machine has gone through the processes of coarse grinding, fine grinding, and superfine grinding to make the ground peanut butter more delicate and smooth.

- This machine is widely applied for the emulsification and grinding of various nuts and oily substances.

- The food contact parts are made of food-grade stainless steel, which is corrosion-resistant, safe, and hygienic.

- The particle size of the materials processed by this machine can reach 2-60 microns, and the homogeneity can reach more than 95%.

- This chili paste grinding machine can control the fineness of food processing by adjusting the distance between the stator and rotor.

Applications

- Food Industry: Aloe vera, pollen, pineapple, sesame, fruit tea, ice cream, mooncake filling, butter, jam, fruit juice, soy products, peanut milk, dairy, beverages, chicken paste, animal hides.

- Chemical Industry: Paints, pigments, dyes, lubricants, adhesives, detergents, plastics, explosives, emulsified asphalt.

- Daily Chemicals: Toothpaste, detergents, shampoo, cosmetics, soaps, and shoe polish.

- Pharmaceutical Industry: Syrups, nutritional liquids, medicinal pastes, biological products, cod liver oil, pollen, royal jelly, vaccines, creams, oral solutions, injections, emulsions.

- Other Industries: Construction coatings, plastics, textiles, paper, bio-chemicals, nano-materials, and research institutions.

Technical Parameters

| Model | Voltage (V) | Power (KW) | Capacity (KG/h) | Weight (KG) | Dimensions (mm) |

|---|---|---|---|---|---|

| GN-50 | 380/50HZ | 1.5 | 10–30 | 65 | 610×400×700 |

| GN-80 | 380/50HZ | 4 | 50–100 | 170 | 850×450×930 |

| GN-110 | 380/50HZ | 7.5 | 100–200 | 220 | 850×450×1050 |

| GN-130 | 380/50HZ | 11 | 200–300 | 350 | 1000×500×1100 |

| GN-180 | 380/50HZ | 18.5 | 500–800 | 440 | 1050×550×1100 |

| GN-220 | 380/50HZ | 30 | 600–900 | 580 | 1080×600×1350 |

| GN-240 | 380/50HZ | 37/45 | 1000–1500 | 800 | 1400×600×1350 |

| GN-300 | 380/50HZ | 75/90 | 3000–5000 | 1200 | 1500×700×1450 |

Our power voltage and plugs can be customized, and the machine materials can be made of stainless steel 304 or stainless steel 201. Welcome to contact us for more details!

Working Principle of the Chili Sauce Grinding Machine

The chili sauce grinding machine works through the relative motion between a high-speed stator and rotor. As the material passes through the gap under the influence of its own weight, air pressure, and centrifugal force, it is subjected to strong shearing, friction, impact, and high-frequency vibration forces. The material is effectively crushed, dispersed, emulsified, and mixed, achieving the desired ultrafine grinding effect.

The grinding chamber typically has three grinding zones:

- Coarse grinding zone: Initially crushes the material.

- Fine grinding zone: Further refines the material.

- Ultrafine grinding zone: Achieves ultrafine grinding and allows for recirculation to meet higher processing requirements.

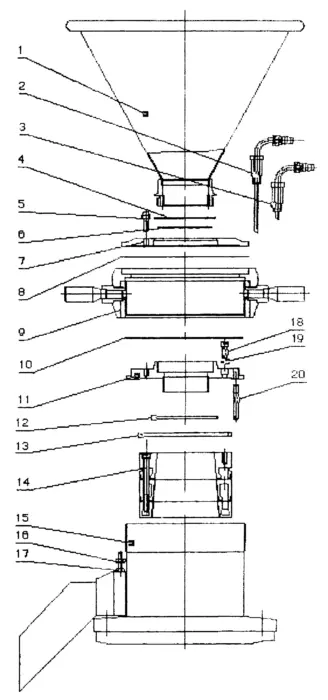

Structure Composition

The chili grinding machine mainly consists of the following parts:

Feeding and Discharge System

- Hopper: Entry point for materials.

- Discharge Flange / Hopper: Exit for processed materials; optional recirculation discharge.

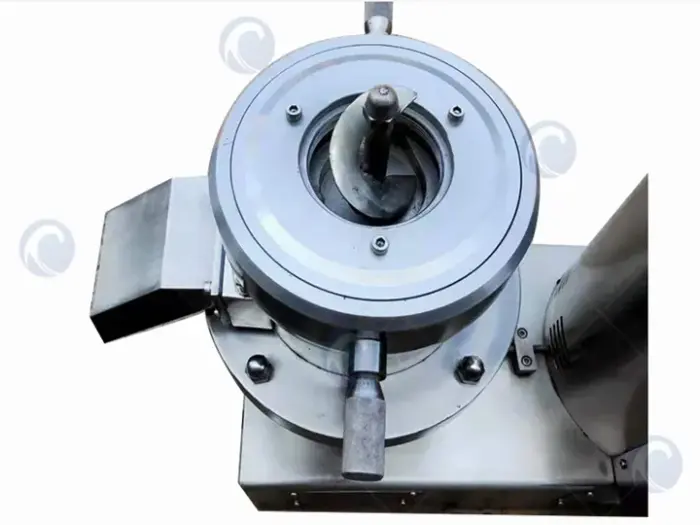

Grinding System

- Stator and Rotor: Core processing parts; different materials and tooth shapes available for various materials and requirements.

- Adjustment Ring and Scale: Fine-tune the gap between stator and rotor to control product size.

- Cooling System: Prevents overheating and keeps the material stable.

Drive System

- Motor and Main Shaft: Provides power; some models offer explosion-proof motors.

- Reducer or Transmission: Stabilizes speed and ensures uniform grinding.

Sealing and Safety System

- O-ring, Gasket, Cover Screws: Prevent material leakage.

- Limit Screws and Lock Nuts: Fix the rotor gap to ensure precision and safety.

Machine Body Structure

- Main Base and Body: Support and fix core parts.

- Bearings, Bearing Covers, and Spring Washers: Ensure smooth rotor operation.

- Pulley and Retaining Ring: Power transmission components.

- Hopper

- Water inlet tap

- Water discharging tap

- O-sealing ring

- Shaped screw cap

- Sealing inlier

- Fixing ring

- Sealing inlier

- Adjusting ring

- Sealing inlier

- Stator stand

- O-ring

- O-ring

- Stator assembly

- Main part

- Limit screws

- Locking nut

- Hexagon screw

- Spring washer

- Orientation column

Key Features of the Chili Sauce Grinder

Premium Material Construction

Major components are crafted from high-quality stainless steel, ensuring excellent corrosion resistance, non-toxicity, and long-lasting durability

Precision Stator and Rotor

The stator and rotor are processed using advanced machining and heat treatment techniques for high precision and extended service life.

Durable Grinding Head

The rotor (grinding head) is made of 9Cr18 stainless steel, providing superior wear resistance and long-term reliability.

Versatile Material and Structure Options

Stators and rotors can be customized with different materials, grinding, and shearing structures, allowing flexible adaptation to specific processing needs.

Adjustable Grinding Gap

The working gap between stator and rotor can be finely adjusted with a dialed adjustment ring, ensuring precise control and consistent product quality.

Stable Operation

Stoppers and locking devices secure the adjustment ring and main seat, maintaining a stable stator-rotor gap during continuous operation.

Flexible Feeding and Discharge Options

Standard hoppers, pipe outlets, and recirculation systems provide maximum flexibility for diverse production requirements.

Motor Options

Choose between a standard motor or an explosion-proof motor to meet different safety and operational needs.

Reliable Standard Motor

Equipped with a dependable standard motor, delivering consistent power for smooth and stable operation.

Independent Motor and Shaft Design

The motor and main shaft are separately driven, allowing optimal speed adjustment for efficient processing.

Integrated Cooling System

The built-in cooling system preserves material properties, preventing overheating and ensuring optimal processing performance.

User-Friendly Design

The machine features stable performance, easy operation, and simple maintenance, making it highly efficient and convenient for long-term use.

Why Choose the Taizy Chili Sauce Grinding Machine?

- Over 20 Years of Experience: Taizy has more than two decades of expertise in designing and manufacturing chili sauce grinding machines and food processing equipment.

- High-Quality Equipment: Made from premium materials, our machines are corrosion-resistant, durable, and deliver stable, reliable performance.

- Advanced Technology: Precision machining, heat treatment, and innovative stator-rotor designs ensure ultrafine grinding, emulsification, and homogenization of chili sauce.

- Customizable Solutions: Motor type, rotor/stator material, gap adjustment, and feeding/discharge methods can all be tailored to meet your production needs.

- Reliable Performance: Stable operation, high processing efficiency, and advanced cooling systems maintain product quality while minimizing downtime.

- User-Friendly Design: Easy to operate, simple to maintain, and safe, suitable for both small and large-scale production.

Taizy also provides a chili stem removing machine for chili processing. If you are interested in our products, please contact us using the form on the right.