The sesame seed cleaning machine is specially designed for the primary processing of sesame seeds. It removes dust, debris, and other impurities attached to the seeds, and is also known as a water-washing sesame machine, sesame water cleaner, or sesame rinsing machine.

This machine is developed based on the growth and physical characteristics of sesame seeds. By using spiral blades for stirring, the sesame seeds can be thoroughly cleaned without damage.

The sesame seed cleaning machine is widely used in primary sesame processing, cleaning before roasting, cleaning before oil pressing, and in sesame paste production lines. It is an essential machine for producing sesame paste, sesame oil, and sesame-based foods.

Its cleaning capacity ranges from 500 to 1000 kg/h, and both small and large models are available.

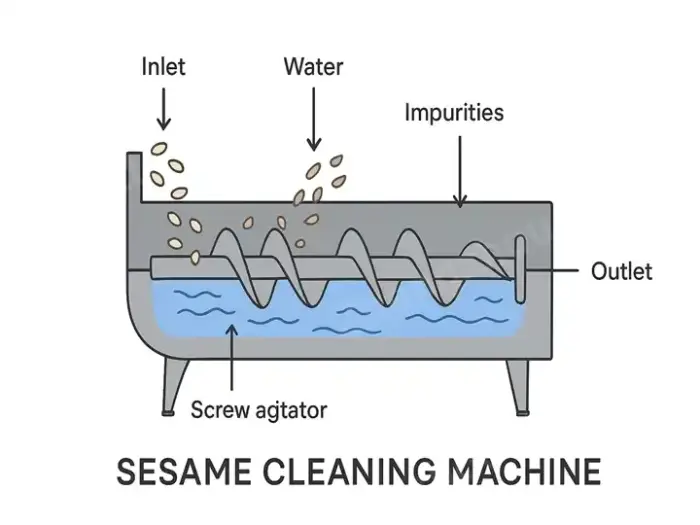

Working principle of the sesame seed cleaning machine

Feeding: Sesame seeds mixed with sand and stones enter the cleaning machine through the feed inlet. The spiral stirring device evenly disperses the seeds.

Spiral stirring and cleaning: The spiral agitator in the cleaning tank continuously rotates, stirring and turning the sesame seeds in water. During this process, surface dust, impurities, and sand are gradually washed away.

Impurity separation: Sesame seeds are light in weight, so the light impurities are carried away by the water flow, while heavier impurities settle or are discharged through the impurity outlet.

Spiral conveying: The spiral agitator continuously stirs and slowly pushes the cleaned sesame seeds toward the discharge outlet.

Structure of the sesame cleaning machine

The sesame seed cleaning machine consists of a feed inlet, spiral stirring device, cleaning tank, spraying system, impurity outlet, and discharge outlet.

Feed inlet

Located at the front of the machine, used to evenly feed sesame seeds into the machine.

Spiral stirring device

The core component of the machine is responsible for stirring the sesame seeds in water, creating friction and movement to remove surface impurities effectively.

Cleaning tank

Made of stainless steel for corrosion resistance, it holds water and sesame seeds, where the cleaning process takes place.

Impurity outlet

Discharges the impurities removed from the sesame seeds.

Spraying system

Installed inside the cleaning tank, it continuously supplies water and maintains water circulation during cleaning.

Discharge outlet

The cleaned sesame seeds are discharged from this outlet, usually in a continuous process.

Core features of the sesame seed washing machine

Food-grade stainless steel construction: Both the spiral stirring device and cleaning tank are made of food-grade stainless steel, corrosion-resistant, durable, and ensure no contamination of sesame seeds.

Customizable material and size: Supports customization of materials and dimensions according to requirements.

Continuous operation: Can operate continuously and seamlessly integrate with roasting, oil pressing, and other production processes.

High-pressure spraying nozzles: Facilitate easy separation of sesame seeds and impurities, reducing water usage and manual labor.

Gentle stirring: prevents sesame seeds from breaking during cleaning.

Full line compatibility: Can be coordinated with all machines in a sesame production line.

Easy operation: Simple to use; only manual feeding is required.

Universal wheel design: Wider and thicker universal wheels reinforced with stainless steel for durability and practicality.

Wide application: Suitable not only for sesame but also for other grains and granular products such as soybeans and cereals.

PLC control box with knob design: Easy to understand and operate.

High-power fan: Quickly blows away impurities and assists in drying sesame seeds.

Technical specifications

| Model | TZ-SS500 | TZ-SS1000 |

| Power | 1.5KW | 2.2KW |

| Voltage | 380V | 380V |

| Fan Power | 2.2KW | 2.2KW |

| Capacity | 500kg/h | 1000kg/h |

| Size(mm) | 2800*650*2150 | 2960*560*2600 |

| Spindle speed(rev/min) | 750 | 750 |

| Dry film specifications(mm) | 400 | 400 |

The above are our standard models. Power supply, voltage, plug type, dimensions, and wheels can all be customized. If you would like to learn more, please contact us through the pop-up.

Applications of the Sesame cleaning machine

The machine is not only used for cleaning and sifting sesame seeds but can also clean various grains with a diameter of less than 1 cm, such as kidney beans, soybeans, corn, peanuts, rice, buckwheat, millet, wheat, and rapeseeds.

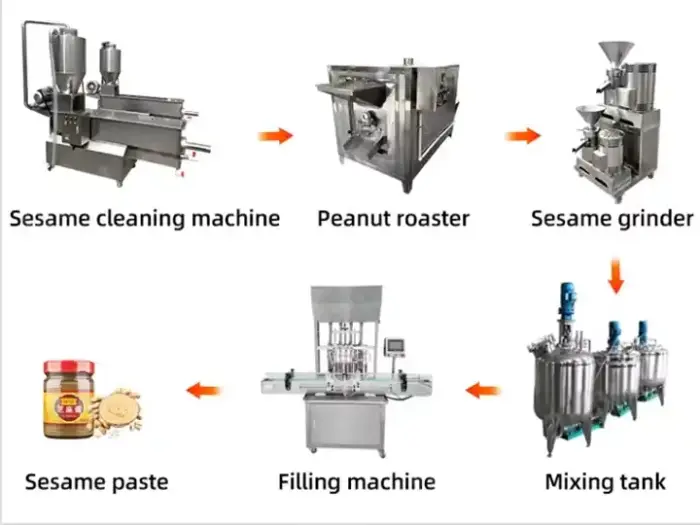

Deep processing of sesame seeds

Cleaned sesame seeds can be processed into value-added products such as sesame paste and sesame oil.

This process involves machines such as a sesame roasting machine and a sesame grinding machine, among others.

Why clean sesame seeds?

Remove impurities and ensure purity

During harvesting and transportation, sesame seeds can be mixed with dust, sand, small stones, straw fragments, husks, and other impurities. Cleaning effectively removes these foreign materials, ensuring quality for subsequent processing.

Ensure food safety

Cleaning removes surface residues such as pesticides, dust, and harmful microorganisms, meeting food hygiene standards.

Improve roasting and oil quality

Impurities and dust entering the roasting process can affect the color, taste, and even produce off-flavors in sesame. In oil pressing, uncleaned sesame can reduce oil purity, flavor, and yield.

Prevent equipment damage

Small stones or hard impurities in sesame can cause mechanical wear or damage in roasting or oil pressing machines. Cleaning helps extend equipment lifespan.

Ensure smooth subsequent processes

Cleaned sesame seeds are more uniform and hygienic, facilitating dehulling, roasting, and oil extraction.

Why choose Taizy?

- 14+ years of export experience in machinery

- 100+ professional R&D team and staff

- 10000+ square meters lab and production workshop

- CE, IS09001,1S014001 certificated

- 5000+ cooperative customers

- 12-month warranty

- Comprehensive pre-sales, in-sales, and after-sales service

- Free supply of vulnerable spare parts

- Mechanical test report available

F&Q

Are you a trading company or a manufacturer?

We are a factory, offering high-quality machines at factory prices.

When can we receive the machines after payment?

Delivery time depends on the exact machines you confirm.

If we purchase your machines, what warranty or quality guarantee do you provide?

We provide a 1-year warranty on high-quality machines and offer lifetime technical support.

How do you provide technical support?

24/7 technical support via phone and email

Friendly English manual

Engineers available for on-site service overseas

How do you handle after-sales service?

Machines are properly adjusted before shipment, allowing immediate use. Free training and guidance on our machines are available at our factory. You can also receive free advice and consultation via email, fax, or phone, with lifetime technical support and service.

What about spare parts?

After all arrangements, we provide a spare parts list for your reference.

Does your company accept customization?

We have an excellent design team, and we can accept OEM.

What about the shipping methods?

For urgent order and light weight, you can choose express: FEDEX, TNT, DHL or EMS; for heavy weight, you can choose by air or by sea to save cost.

When to deliver the goods after the order is placed?

It depends on the quantity of the product, generally we will arrange shipment within 5 to 10 days after receiving payment.

How can I get to your factory?

We are in No.1394 East Hanghai Road, Economic-technological Development Area, Zhengzhou, China. And we can provide free and considerate receptions for you.