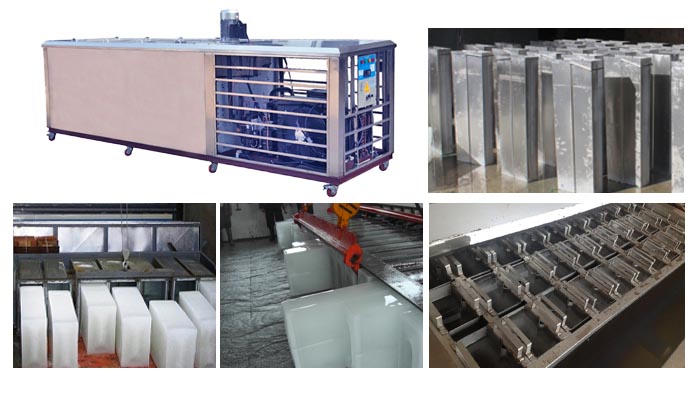

Mashine ya kutengeneza vitalu vya barafu ni vifaa maalum vya kutengeneza vitalu vya barafu. Vipande vya barafu vinavyozalishwa na mashine hii vinaweza kutumika kwa ajili ya kuhifadhi chakula, usindikaji, kutazama, na madhumuni mengine. Ukubwa wa cubes za barafu zinazozalishwa na mashine hii zinaweza kubinafsishwa kulingana na mahitaji. Kuna aina mbalimbali za ukungu wa barafu, kama vile 5kg, 10kg, 15kg, n.k., na pato ni 1t, 3t, 5t, 10t, n.k. Matofali ya barafu yanayotolewa na mashine ya kutengeneza barafu ya viwandani ndiyo makubwa zaidi kati ya bidhaa za barafu. . Kulingana na mbinu tofauti za friji, vifaa vya kutengeneza vitalu vya barafu vya kibiashara vina aina ya kupoeza moja kwa moja na mashine ya kutengeneza vitalu vya barafu aina ya brine.

Maombi ya mashine ya kutengeneza vitalu vya barafu vya kibiashara

Matofali ya barafu yanayotolewa na mashine ya kuzuia barafu yana matumizi mengi sana. Inaweza kutumika katika usindikaji wa chakula, kuhifadhi bidhaa za majini, kupoeza, kupoeza, na kutazama sanamu za barafu. Inatumika sana katika bandari, bandari, viwanda vya usindikaji wa chakula, uvuvi baharini, na maeneo mengine mengi. Ukubwa wa vipande vya barafu vinaweza kubinafsishwa na vinaweza kusagwa katika aina mbalimbali za cubes za barafu kulingana na mahitaji tofauti.

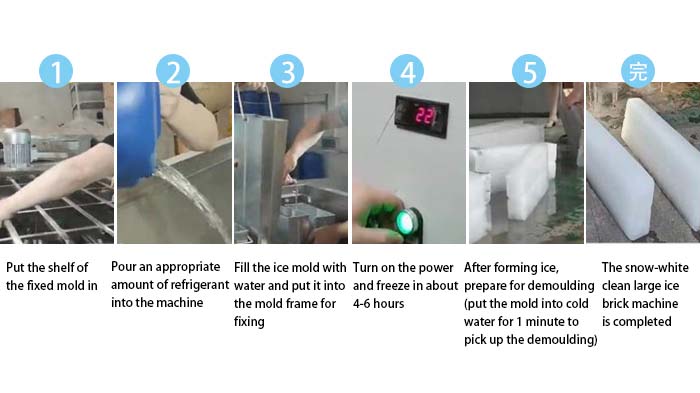

Hatua za kutengeneza barafu

- Weka rafu ya mold fasta katika mashine ya matofali ya barafu

- Mimina kiasi kinachofaa cha jokofu kwenye mashine

- Jaza ukungu wa mchemraba wa barafu na maji na uweke kwenye sura ya ukungu ili kuirekebisha

- Washa nishati ili kutengeneza barafu, saa 4~6 ili kukamilisha kutengeneza barafu

- Weka ukungu kwenye maji baridi na loweka kwa dakika moja ili kuunda kizuizi cha barafu

Aina za mashine ya kutengeneza vitalu vya barafu

Kwa mujibu wa mbinu tofauti za friji, mashine za kuzuia barafu zina aina mbili: aina ya friji na aina ya brine. Mashine ya kuzuia barafu ya moja kwa moja ni njia ya moja kwa moja ya kutengeneza barafu. Inatumia kubadilishana joto moja kwa moja kati ya friji na maji kutengeneza barafu. Mashine ya matofali ya barafu ya brine hutumia utengenezaji wa barafu usio wa moja kwa moja. Inatumia maji ya chumvi kama njia ya kubadilishana joto zaidi. Baada ya kupozwa na maji ya chumvi, maji kwenye ndoo ya barafu huganda na kuwa barafu.

Mashine ya kuzuia barafu ya maji ya chumvi ya moja kwa moja ya VS

Kwa kuwa mashine za kuzuia barafu moja kwa moja hutumia jokofu na maji moja kwa moja kubadilishana joto, maji ya chumvi hayahitajiki kama njia ya kati ya kupoeza, na mchakato wa kutengeneza barafu hauna uchafuzi wa mazingira. Zaidi ya hayo, aloi ya alumini inayotumiwa kwenye mashine inalingana na usalama wa chakula, usafi, na usalama, na vipande vya barafu vinavyozalishwa vinaweza kuliwa moja kwa moja. Kwa hiyo, matofali ya barafu yaliyotengenezwa kwa kutumia matofali ya barafu ya baridi ya moja kwa moja yanaweza kutumika katika sekta ya usindikaji wa chakula.

Kitengeneza barafu ya brine hutumia brine kama chombo cha kubadilishana joto, na uzalishaji wake ni mkubwa kuliko ule wa aina ya kupoeza moja kwa moja. Kwa kuongezea, mashine ya kuzuia barafu ya maji ya chumvi inahitaji matumizi ya vidimbwi vya maji ya chumvi, uwekaji wa korongo za angani, na vifaa vingine vya ziada. Kwa ujumla inafaa kwa mimea kubwa ya kutengeneza matofali ya barafu.

Faida za mashine ya kutengeneza vitalu vya barafu vya viwandani

- Mashine hii yote inachukua muundo unaofaa wa chuma, nguvu ya juu, na si rahisi kuharibika.

- Mashine ya kuzuia barafu inachukua njia ya kulehemu au ya riveting ili kuboresha maisha ya huduma ya mashine.

- Kupitisha safu ya povu ya cyclopentane yenye unene, tenga kwa ufanisi nishati ya nje na uwe na athari nzuri ya insulation ya baridi.

- Mwili wake wote huchukua chuma cha pua, ambacho kinaweza kutayarishwa bila friji ya babuzi, ambayo ni ya afya na ya usafi.

- Kupitisha kujazia, bomba nene safi ya shaba, na muundo wa mfumo wa majokofu, maradufu kasi ya friji na utendakazi thabiti.

- Nyenzo za ukungu wa barafu na saizi ya ukungu wa barafu zinaweza kuchaguliwa kulingana na mahitaji ya wateja.

- Evaporator inachukua shaba safi, na athari ya moja kwa moja ya baridi ni bora.

- Mashine hii ya viwanda ya kutengeneza vitalu vya barafu ina aina mbalimbali za mifano ya pato, ambayo inaweza kukidhi mahitaji ya watumiaji mbalimbali.

Vigezo vidogo vya mashine ya kutengeneza barafu

| Mfano | TZ-1 | TZ-2 |

| Uzito wa mfano | 10kg | 10kg |

| Ukubwa wa mfano | 260*70*670mm | 260*70*670mm |

| Idadi ya mifano | 16 | 32 |

| Ukubwa wa mashine | 2.86*0.62*1.05m | 2.79*1.025*1.115m |

| Wakati wa barafu/h | 4 | 4 |

| Jamii ya friji | R22 | R22 |

| Nguvu iliyokadiriwa/kw | 6 | 8.5 |