The eddy current cleaning machine uses swirling and air bubbles to clean green leafy vegetables. It has the advantages of a bubble vegetable and fruit washing machine and a swirling vegetable washing machine. The vortex fruit and vegetable washing machine are suitable for washing whole and cutting vegetables. It is widely used to clean fruits, vegetables, aquatic products, medicinal materials, and other products. The whole machine adopts high-quality food stainless steel, which meets food safety and sanitation standards. The machine is designed with bubble cleaning on the basis of the traditional vegetable cleaning machine, which makes the cleaning more efficient and thorough. It completely removes the silt and pesticide residues on the surface of the material and is ideal equipment for the vegetable cleaning and processing industry.

Eddy current leafy vegetable cleaning machine application

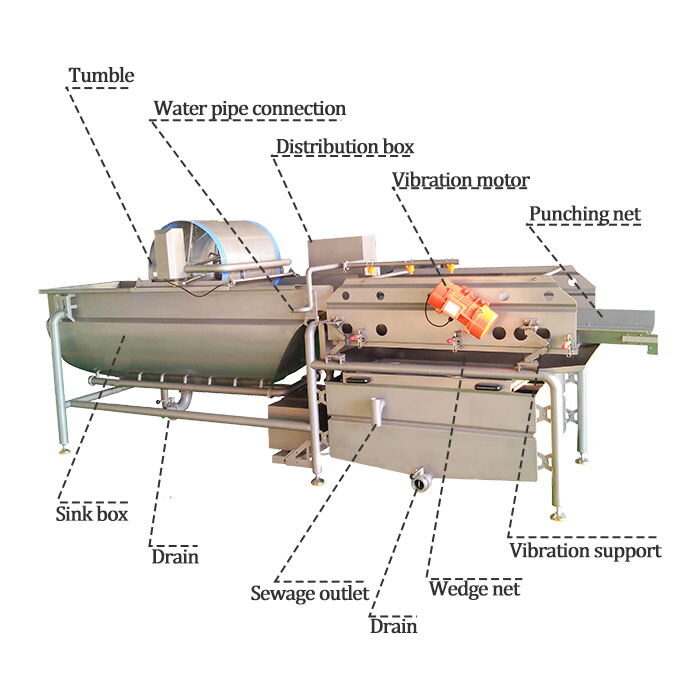

The vortex vegetable washing machine mainly consists of two parts: cleaning and removing impurities and vibration and draining.

The cleaning area matches with vortex and bubble cleaning, which widely applies in the cleaning of leafy vegetables, rhizomes, and pickled fruits and vegetables. For example, cabbage, lettuce, spinach, radish, kohlrabi, etc. This machine is not only suitable for cleaning the entire dish, but it can also clean the cut, shredded, and sliced dishes. In addition, the chopped vegetables will not stick to the mesh belt after washing.

Structure and working principle

The eddy current cleaning machine is mainly composed of a tank body, an inner tank body, a sand and mud isolation net, a lifting device, a bubble generating device, and other components.

Working principle: The vortex leafy vegetable washing machine is mainly composed of two parts: vortex cleaning and vibration draining. The vortex cleaning the main body generates vortex and bubbles to clean vegetables. The inlet and both sides of the tank equip with spray pipes, and the high-pressure water pump supplies water under the action of spraying water to produce a swirling state of the water in the tank. The swirling water pushes the vegetables in a spiral motion in the tank for cleaning. After cleaning the material, it is pushed forward to the vibration draining place for draining under the action of hydrodynamic force.

The vibration drain device uses a vibration motor to vibrate the main body. Therefore, the vegetables on the draining device also achieve the draining function with the vibration of the machine.

Vortex vegetable washing machine features

- The vortex cleaning method has the dual advantages of swirling and bubble cleaning, and will not damage the vegetables.

- The spiral mixed water flow cleans vegetable materials, extends the cleaning path, and saves water sources;

- It has a wide range of uses and can be used to clean various forms of vegetables and fruits;

- Vegetables flow out with water to reduce mechanical damage;

- Automatic slag conveying improves the efficiency of cleaning vegetable dregs;

- Using cylindrical pillars and concealed circuits, the appearance of the equipment is more atmospheric;

- The eddy current cleaning machine overcomes the clumping phenomenon of the traditional vegetable washing machines when washing vegetables. The high-pressure water bubble has the function of separating the vegetables into groups, which solves the drawback that the washing machine can only clean the cut vegetables.

- The vibration drain device can be adjusted, which meets the needs of cleaning and transporting different light and heavy materials.

Parameters of eddy current vegetable washing machine

| Capacity | 1000kg/h |

| Size | 4200×1120×1600 |

| Power | 4.4KW |

| Voltage | 380V |

| Frequency | 50HZ |

| Import and export height | 1550/1200 |

| Weight | 600KG |

Operation steps of vortex vegetable cleaning machine

- Clean the water tank and fill it with water until the water overflows from the overflow port in the main tank

- Start the conveyor mesh belt motor to make the mesh belt run normally in the correct direction

- Start the vortex pump to inject the generated air into the water tank to generate tumbling bubbles

- Open the sprinkler pipe valve, let the water spray evenly on the mesh belt

- Check the operation of each part and start the cleaning work after confirming the normal operation.