Kichujio cha juisi ya skrubu ya kibiashara hutumia hasa kubana skrubu ili kuponda na kukamua juisi hiyo. Inatumika sana kwa kufinya juisi kutoka kwa matunda na mboga mbalimbali. Na mashine pia inaweza kuongeza kifaa cha kusagwa ili kuongeza ufanisi wa uchimbaji wa juisi. Mashine ya kukamua juisi ya matunda ya ond ina nguvu ya juu ya kubana na ufanisi wa juu wa uchimbaji wa juisi. Mashine huweka kontena la juisi, na juisi na pomace baada ya kubana hutenganishwa kiotomatiki.

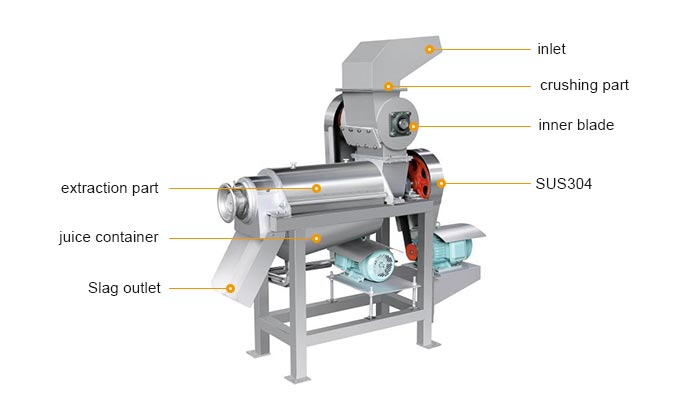

Muundo wa mashine ya extractor ya juisi ya screw

The screw fruit juicer na kusagwa hasa ni pamoja na crusher na juicer screw. Kifaa kilichovunjika kinaweza kulinganishwa kulingana na mahitaji ya mteja. Sehemu nzima ya juicer imeundwa hasa na juicer ya screw chini. Juicer ni pamoja na sura, hopper, screw, chujio, juicer, nyimbo ya slag, na vipengele vingine.

Je! Mashine ya kutolea maji ya bisibisi inafanya kazi gani?

Ikiwa unaponda na kufinya tufaha na mananasi, tulipendekeza kwamba uongeze kifaa cha kusagwa. Wakati wa kufinya juisi, matunda huvunjwa kwanza kwa njia ya kusaga. Matunda yaliyovunjika huingia kwenye juicer ya ond na inasukuma mbele kwa njia ya ond. Kadiri skrubu inavyosukuma nyenzo mbele, mwanya wa mbele unakuwa mwembamba na mwembamba, kwa hivyo skrubu na ukuta wa mashine hubana na kuponda tunda. Juisi katika matunda hutiwa nje. Juisi iliyopuliwa inapita nje ya chombo cha juisi, na mabaki iliyobaki hutolewa kutoka kwa pengo.

Maombi ya juicer ya matunda ya viwandani

Juisi ya matunda ya viwandani ina matumizi mbalimbali, na inaweza kutumika kwa ajili ya uchimbaji wa juisi mbalimbali za matunda na mboga. Kikamulio cha skrubu kinaweza kutumika kutoa juisi za matunda kama vile tufaha, peari, machungwa na mananasi. Inaweza pia kutumika kwa ajili ya kuchimba juisi za mboga kama vile nyanya, celery, mchicha na tangawizi.

Faida za extractor ya juisi ya screw

- Nguvu kubwa ya kufinya, juisi ya haraka.

- Kutumia chuma cha pua cha daraja la chakula, maisha marefu ya huduma, kazi ya nafasi ndogo, muundo mzuri.

- Inaundwa na crusher na juicer ya screw, na kazi ya kusagwa, juisi inaweza kupunguzwa moja kwa moja kwa matunda makubwa.

- Mashine ina vifaa vya chombo cha juisi, na juisi hutolewa kutoka kwenye chombo cha juisi baada ya kufinya, ambayo hupunguza uchafuzi wa juisi.

- Mabaki ya juisi hutenganishwa kiotomatiki ili kuzuia mabaki ya matunda kuchafua juisi.

- Tunatumia mashine zilizobinafsishwa, ikiwa una mahitaji maalum ya mashine, tunaweza pia kukuwekea mapendeleo mashine.

Ufungaji, uendeshaji na matengenezo ya mashine

- Weka juicer ya screw usawa juu ya ardhi na kurekebisha kwa screws.

- Wakati wa kuanza vifaa, kurekebisha indenter ili kuongeza pengo la annular, na kisha pengo hupungua hatua kwa hatua. Baada ya kufikia mahitaji ya kiteknolojia, tumia kuvunja ili kurekebisha nafasi ya kiti cha kubeba handwheel.

- Dumisha kulisha kwa usawa, na ukataze kabisa vitu vigumu kuingia kwenye hopa ili kuzuia uharibifu kwenye skrini.

- Baada ya kila kazi, lazima utumie maji na brashi ili kusugua chujio.

- Badilisha fani mara kwa mara na uongeze grisi safi. Joto la kawaida la matumizi ya kuzaa linapaswa kuwa chini ya digrii 75.

Vigezo vya mashine ya kutolea maji ya matunda aina ya screw

| Mfano | TZ-0.5 | TZ-1.5 | TZ-2.5 |

| Ukubwa | 1100*350*1280mm | 1280*550*1485mm | 1320x700x1585mm |

| Voltage | 3800V50HZ | 380V/50HZ | 3800V50HZ |

| Uwezo | 500KG/H | 1500KG/H | 2.5T/H |

| Nguvu ya kubana | 1.5KW | ~ | ~ |

| Nguvu ya kuponda | 0.75KW | 2.2+4KW | 11KW |

| Uzito | 200KG | 550KG | 480KG |