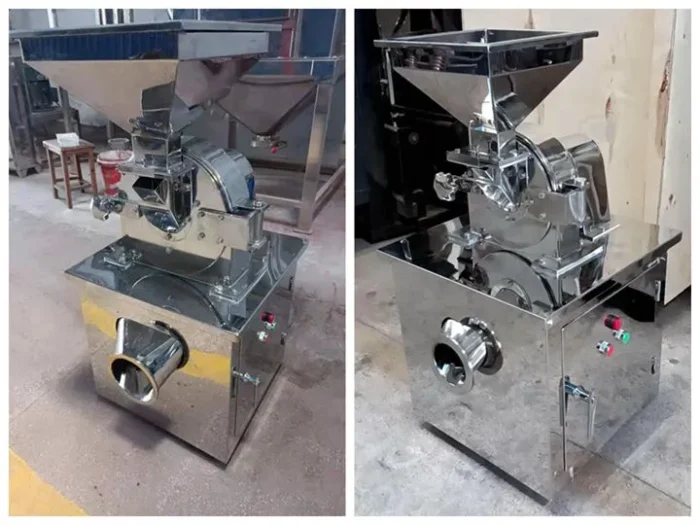

ステンレス鋼の野菜粉砕機は、さまざまな穀物、スパイス、ナッツ、その他の製品の粉砕に主に使用されます。高速回転する可動歯ディスクと固定歯ディスクの相互作用を利用して、材料を粉末粒子に粉砕します。

この工業用ニンニク粉末粉砕機は、耐腐食性と清掃の容易さを考慮し、食品グレードの304ステンレス鋼で作られています。衛生的で汚染のない処理を保証し、細かさは10から120メッシュまで調整可能で、出力は10–3000 kg/hを実現します。

この売れ筋の野菜粉砕機は、スパイス、コショウ、チリ、生姜、ニンニク、コーヒー豆、ココア豆、ハーブ、茶葉、小麦、化学材料、乾燥果物などの乾燥材料の粉砕に最適です。粉末は粉砕室から直接排出され、異なるメッシュスクリーンで粒度を調整できます。操作は簡単で、安定した性能、低騒音、優れた粉砕効率を提供します。

野菜粉砕機の特徴

- ステンレス製の製粉機の内壁は滑らかな表面を実現するように処理されており、粉砕された粉末は国家基準により準拠し、GMPの要件を満たしています。

- ステンレス鋼ミルには、さまざまな粉砕材料に応じたさまざまなギア プレート スタイルがあり、さまざまな顧客のニーズを満たすことができます。

- ギアプレートの表面は滑らかで、耐摩耗性、耐腐食性、耐久性に優れています。食品、医療、飼料、化学工業など様々な分野で幅広く使用されています。

- 良好な粉砕効果、高い作業効率、低労働強度、操作が便利です。

野菜粉末ミルの幅広い用途

この商用野菜粉末ミルは、さまざまな乾燥材料の粉砕に使用できます。この小型ミルは、塩粉、ジンジャーパウダー、ニンニク粉、調味料粉、コーン粉など、さまざまな食品粉末の処理によく使われます。

ゴマ、クルミ、ピーナッツ、アーモンド、ひまわりの種などの高油分材料は単独で粉砕しないでください。低油または油分の少ない材料と混合し、油分を25%以下に保つ必要があります。高油分の大きな材料の場合は、最初にクラッシャーまたはステンレス鋼の粗粉砕機で粗破砕し、その後超微粉砕機でさらに粉砕してください。

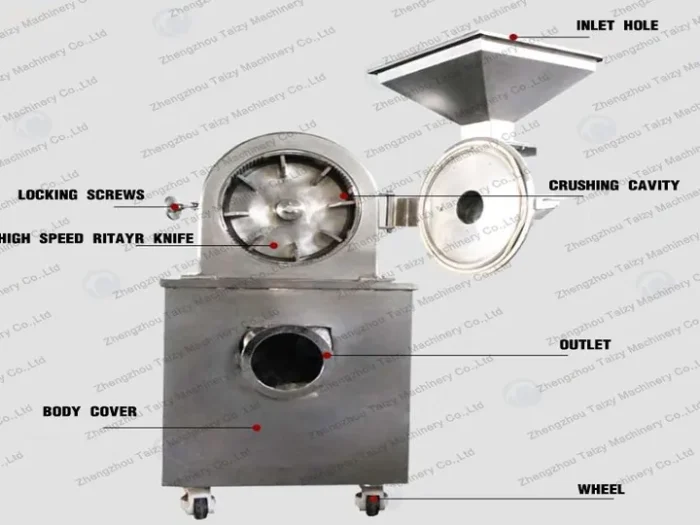

野菜粉砕機の構造

野菜粉砕機は、一般的にホッパー、高速回転刃、粉砕室、ロッキングスクリュー、機械カバー、排出口、車輪、手動およびスマートコントロールボタンで構成されています。

- ホッパー: 原材料の給餌用。

- 高速回転刃: 野菜を粉末またはペーストに粉砕するために。

- 粉砕室: 材料が粉砕・粉末化される場所。

- ロッキングスクリュー: 機械部品を固定するために。

- 機械カバー: 内部コンポーネントを保護し、安全性を確保。

- 排出口: 粉砕された材料が集められる場所。

- 車輪: 移動が容易。

- コントロールボタン: 操作用の手動およびスマートコントロール。

小型野菜粉末ミルのパラメータ

| モデル | ユニット | 10B | 20B | 30B | 40B | 50B | 60B | 70B |

| 生産能力 | kg/h | 20-50 | 60-150 | 100-300 | 160-800 | 250-1200 | 500-1500 | 800-2000 |

| 給餌サイズ | mm | 6 | 6 | 2-10 | 2-12 | 2-15 | 2-15 | 2-15 |

| 粉砕の細かさ | メッシュ | 10-120 | 10-120 | 10-120 | 10-120 | 10-120 | 10-120 | 10-120 |

| ワイト | kg | 120 | 200 | 280 | 400 | 500 | 620 | 880 |

| 主軸速度 | r/min | 4500 | 4500 | 3800 | 3400 | 3200 | 3200 | 3200 |

| モーター出力 | キロワット | 2.2 | 4 | 5.5 | 11 | 15 | 22 | 37 |

| 全体寸法 L*b*h | mm | 450*550*900 | 550*600*1250 | 630*700*1400 | 800*900*1550 | 850*850*1600 | 1000*900*1680 | 1200*1100*1800 |

注意: 材料に応じて異なるメッシュサイズを提供可能です。特殊材料にはカスタマイズも可能です。お気軽にお問い合わせください。

野菜粉末粉砕機の利点は?

高い生産能力

- 小規模から大規模な処理に対応:10B:20–50 kg/h、70B:800–2000 kg/h。

- 小規模な工場から大規模な処理プラントまで対応し、高効率な生産を保証します。

多用途な給餌サイズ

- モデルによって2 mmから15 mmまでの原材料を処理可能。

- ニンニク、タマネギ、ニンジン、チリ、生姜、ハーブ、その他の乾燥野菜に適しています。

調整可能な粉砕細度

- メッシュサイズは10–120メッシュに調整可能。

- 粗粉から超微粉まで、さまざまな用途に対応した粉末を生成します。

耐久性のある構造

- 食品グレードのSUS304ステンレス鋼製で、耐腐食性に優れ、清掃も容易です。

- 堅牢で耐久性のある構造により、長期にわたる安定した運転を保証します。

効率的な高速粉砕

- スピンドルの回転速度はモデルによって3200–4500 r/minの範囲です。

- 高速刃は、均一で乾燥した非塊状の粉末を確保します。

強力なモーターオプション

- モーターの出力は2.2 kW(10B)から37 kW(70B)まで、さまざまな生産要求に対応します。

- 連続高負荷運転をサポートし、最大効率を実現。

コンパクトで移動可能なデザイン

- 寸法は450×550×900 mm(10B)から1200×1100×1800 mm(70B)まで。

- 移動が容易な車輪を装備し、省スペース化。

使いやすい操作性

- 手動とスマートコントロールボタンの両方を備えています。

- 安全で操作が簡単、簡単なメンテナンス。

粒子・野菜粉砕機の仕組みは?

野菜粉末粉砕機は、高速回転する刃またはディスクと固定された部品との衝撃、剪断、摩擦を利用して材料を粉砕します。材料はホッパーを通じて粉砕室に入り、遠心力で自動的に排出されます。

作業動画

なぜタイジーを選ぶのか?

タイジーは、高効率、耐久性、安全性を兼ね備えた工場グレードの野菜粉砕機を提供します。食品グレードのSUS304ステンレス鋼製で、耐腐食性に優れ、清掃も容易です。ニンニク、タマネギ、ニンジン、チリ、生姜、スパイス、ナッツ、乾燥果物など、多様な材料に対応できる調整可能な粉砕細度を備えています。豊富な工場経験を持ち、すべてのタイジー機器はISO9001およびCE認証を取得し、省エネルギーで使いやすく、専門のアフターサービスも提供し、安定した信頼性の高い生産を実現します。

タイジーは、野菜乾燥機、切断機などを含む、野菜処理機器のフルラインを提供しています。お問い合わせをお待ちしています。