Инсталацията за преработка на замразени зеленчуци може да се използва за бързо замразени зелен фасул, зеле, царевица, броколи, филийки моркови и други зеленчуци. Линията за производство на замразени зеленчуци може да запази в най-голяма степен витамините, протеините и другите хранителни вещества в храната. Има висока степен на автоматизация и скоростта на транспортиране на оборудването, бързото време за замразяване и температурата могат да се контролират автоматично. Лиофилизираните плодове и зеленчуци са хрупкави и лесни за пренасяне. Той се превърна в нов фаворит в индустрията за закуски и има широк спектър от сценарии за приложение.

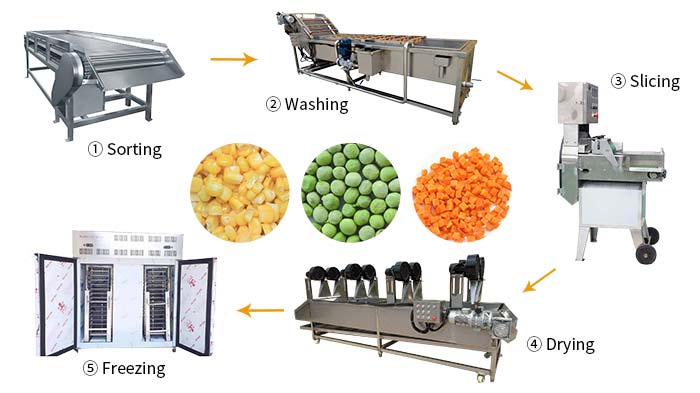

Процес на производство на замразени зеленчуци

Процесът на линията за производство на замразени зеленчуци е: пресяване, почистване, нарязване, сушене на въздух, бързо замразяване, опаковане.

- Изберете гнилите зеленчуци в оригиналния плод и изберете добри зеленчуци.

- Използвайте препарат за почистване на мехурчета от зеленчуци за отстраняване на калта и други замърсявания по повърхността на зеленчука.

- Използвайте многофункционална резачка за зеленчуци да нарежете или нарежете почистените зеленчуци.

- Той използва въздушна сушилня за изсушаване на влагата на повърхността на зеленчуците и след това влиза в машината за бързо замразяване за бързо замразяване.

- Задайте температурата и времето за бързо замразяване, машината за бързо замразяване може автоматично да замразява бързо зеленчуците и автоматично да изхвърля материала.

- И накрая, използвайте опаковъчна машина, за да опаковате и транспортирате замразените зеленчуци за продажба.

Характеристики на завод за преработка на замразени зеленчуци

- Заводът за преработка на замразени зеленчуци използва автоматично машинно производство в целия процес, което може да завърши процесите на почистване, нарязване, замразяване и опаковане наведнъж.

- Цялата поточна линия е надеждна, практична и проста и лесна за поддръжка

- Използва се широко в производството на замразена царевица, зелен фасул, броколи, зеле, картофи, моркови и други продукти

- Цялото оборудване е изработено от хранителни материали, за да отговаря на хигиенните стандарти за износ

- Скоростта на конвейерната лента на машината е регулируема и температурата и времето на замръзване могат да бъдат зададени.