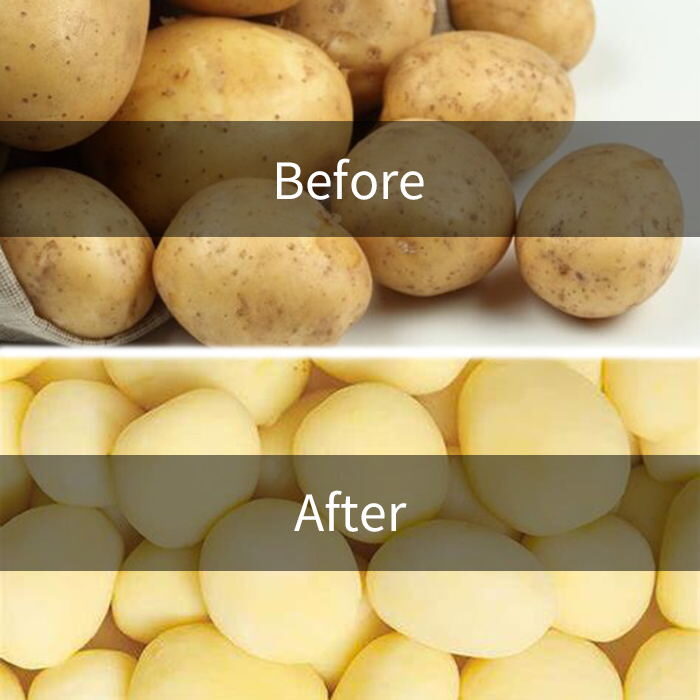

The brush root vegetable washing peeling machine is a machine developed specifically for cleaning root vegetables. The machine has the function of cleaning and peeling. It is suitable for cleaning potatoes, sweet potatoes, cassava, carrots, and other products.

The brush vegetable washing and peeling machine has two types of brushes: a soft brush and a hard brush. It has the characteristics of high output and good cleaning and peeling effect. Moreover, the root vegetable washing machine adopts all 304 stainless steel, which has a stable structure and simple operation.

This machine has a capacity ranging from 150 to 1,000 kg/h and is available in 7 different models.

Applicable raw materials for brush root vegetable washing peeling machine

The brush root vegetable washing machine is used for cleaning and peeling root vegetables. And because the vegetable washing machine has two kinds of brushes: a soft brush and a hard brush, it has the functions of washing and peeling.

The soft brush is mainly used for cleaning root vegetables. It is suitable for cleaning carrots, kelp, potatoes, yams, dates, and other products.

Bristles ya brashi ngumu-bristle ni ngumu zaidi, na ina athari ya kupiga msuguano. Kwa hivyo inafaa kwa kuosha na kusafisha mboga. Kwa mfano, kuosha na kumenya viazi, viazi vitamu, mihogo, tangawizi, beetroot, na bidhaa nyinginezo.

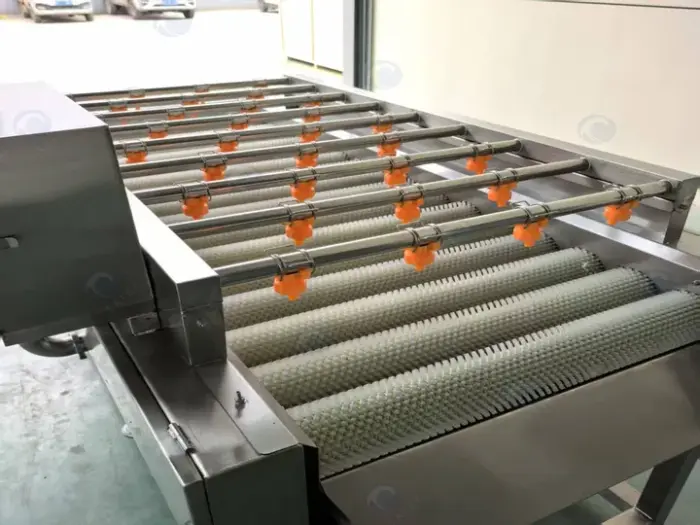

Structure of brush root vegetable washing peeling machine

Commercial brush root vegetable washing machine mainly consists of the frame, spray tube, brush roller, water outlet, motor, and other components.

Working principle

Kanuni yake ya kazi ni: viazi na mboga nyingine za mizizi huingia kwenye mashine, na motor huendesha roller ya nywele na viazi ili kuzunguka. Msuguano unaozalishwa kati ya viazi na roller ya nywele husafisha uchafu kwenye uso wa viazi na kuiondoa. Wakati huo huo, kichwa cha dawa ya shinikizo la juu kinanyunyiza maji yenye shinikizo la juu ili kusafisha uchafu kwenye uso wa viazi. Maji taka yaliyosafishwa, silt, na ngozi za viazi huingia kwenye trei ya matone chini ya mashine. Fungua kusafisha mboga ya mizizi na peeling na valve ya kutokwa kwa upande, na viazi zilizoosha zinaweza kutolewa.

Advantages of brush root vegetable washing peeler machine

- Mashine hutumia nishati kidogo, ni ndogo kwa ukubwa, ni nzuri kwa sura na ni rahisi kufanya kazi.

- It widely applies to cleaning root and potato vegetables such as carrots, sweet potatoes, potatoes, and sweet potatoes.

- Mashine ya kusafisha mboga ina sifa za kiwango kikubwa cha kusafisha kinachofaa, ufanisi wa juu, uhifadhi wa maji, usafishaji endelevu, uendeshaji rahisi, maisha marefu ya huduma n.k.

- The brush roller material is treated with a special process, which is not easily deformed and has good wear resistance.

- The box body adopts high-quality stainless steel, which does not rust.

Technical Specifications

| Mfano | Motor Power (kW) | Overall Dimensions (mm) | Nyenzo | Weight (kg) | Capacity (kg/h) |

|---|---|---|---|---|---|

| TZ-600 | 1.1 | 1450 × 850 × 1000 | 304 Stainless Steel, with Water Tray | 205 | 150 |

| TZ-800 | 1.5 | 1650 × 850 × 1000 | 304 Stainless Steel | 225 | 220 |

| TZ-1000 | 1.5 | 1850 × 850 × 1000 | 304 Stainless Steel | 250 | 300 |

| TZ-1200 | 1.5 | 2050 × 850 × 1000 | 304 Stainless Steel | 260 | 540 |

| TZ-1500 | 2.2 | 2350 × 850 × 1000 | 304 Stainless Steel | 300 | 720 |

| TZ-1800 | 3.0 | 2650 × 850 × 1000 | 304 Stainless Steel | 320 | 900 |

| TZ-2000 | 4.0 | 2850 × 850 × 1000 | 304 Stainless Steel | 350 | 1000 |

Installation and use of brush vegetable cleaning and peeling machine

- After receiving the machine, check whether the screws of each part are loose, and fix the screws of each part.

- Place the brush root vegetable cleaning machine on level ground.

- The bearings and reducer parts of the machine should be regularly filled with lubricating oil to maintain lubrication.

- The machine should be turned on and run for 2 minutes before using it. And the material should be cleaned after confirming that the machine is operating normally.

- At the beginning of cleaning, turn on the water pipe and turn on the spray water pipe for flushing at the same time.

- The handwheel on the transmission geared motor can control the speed of the brush roller.

- When not using the machine, keep it in a clean and dry environment. And the inside and outside of the machine should be kept clean and free of residues.

Mashine ya kusafisha mboga ya skrubu kiotomatiki

The automatic screw brush root vegetable cleaning machine is machine-made on the basis of the hairbrush cleaning machine. The machine adds a spiral on the basis of the brush cleaning machine. The spiral can realise the function of automatic transportation. After the root vegetables enter the machine, while the brush cleans the vegetables, the spiral pushes the vegetables forward. The automatic spiral brush cleaning machine can realise the function of automatic conveying and dispersing materials.

Typical Applications of the Brush Root Vegetable Washing and Peeling Machine

The brush root vegetable washing and peeling machine is widely used in the following processing scenarios:

- Fruit and vegetable pre-processing plants (washing and mud removal)

- Fresh-cut vegetable processing lines

- Pre-treatment for frozen vegetables and dehydrated vegetables

- Potato and sweet potato deep-processing lines

- Central kitchens and food distribution centres

In a complete fruit and vegetable processing line, the brush root vegetable washing and peeling machine is usually used as pre-treatment equipment, working together with cutting machines, blanching machines, and drying machines.

How to choose the right brush root vegetable washing peeling machine?

When selecting a suitable brush root vegetable washing peeling machine, it is recommended to focus on the following factors:

- Type and size of raw materials: Different root vegetables require different brush hardness and roller spacing.

- Processing capacity: Choose the appropriate model based on the required hourly output.

- Peeling requirement: Cleaning-only models and washing & peeling models have different configurations.

- Factory space and water supply conditions: These factors affect machine dimensions and water circulation design.

- Customization support: Such as the number of brush rollers, roller length, voltage, and other specifications.