Lini produksi jus buah menggunakan mesin pengolah jus buah untuk mengekstrak jus dari buah segar. Ia menggunakan buah-buahan dan sayuran segar dan berkualitas tinggi sebagai bahan mentah dan mengekstrak jus dari buah-buahan dan sayuran melalui proses seperti seleksi, pembersihan, dan ekstraksi jus. Taizy menyediakan jus nanas, jus apel, jus anggur, jus jeruk, jus tomat, dan lini produksi jus buah dan sayuran lainnya kepada pelanggan. Kami menyediakan proyek turnkey untuk berbagai lini produksi jus untuk memenuhi kebutuhan pelanggan yang berbeda.

Ikhtisar lini produksi jus buah

1. Bahan baku: apel, nanas, mangga, pir, anggur, tomat, serta buah dan sayuran lainnya

2. Produk jadi: jus buah segar, jus buah pekat

3. Keluaran: 500kg/jam~2t/jam

4. Pengemasan produk jadi: botol kaca, botol PET, kaleng, batu bata aseptik, dll.

5. Mesin produksi: versi sederhana, versi lengkap, versi khusus

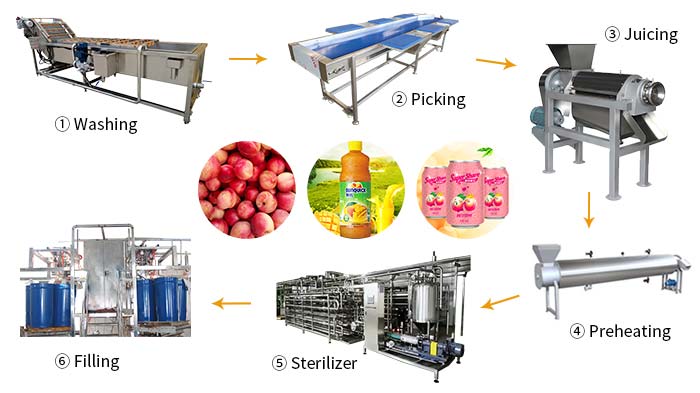

Proses produksi lini produksi jus:

Karena bahan baku yang berbeda memiliki karakteristik struktural yang berbeda, dan banyak pelanggan memiliki proses produksi yang berbeda. Oleh karena itu, kami menyediakan layanan yang disesuaikan untuk pelanggan. Proses produksi sari buah yang biasa dilakukan adalah pencucian buah, penyaringan, pemukulan, sterilisasi, pengisian, dan proses lainnya.

- Gunakan a mesin cuci buah dan sayur untuk membersihkan buah untuk menghilangkan kotoran dan batang.

- Pilih buah yang buruk secara manual dan pilih buah berkualitas tinggi untuk dikocok.

- Gunakan pengocok buah untuk mengocok buah. Struktur mangga yang unik memerlukan penggunaan a mesin pengupas mangga untuk pemukulan. Mesin pemukul ini memiliki pilihan bukaan layar yang beragam, dan pelanggan dapat memilih sesuai dengan kebutuhan sari buah yang dihasilkan.

- Alat sterilisasi jus khusus mencakup alat sterilisasi tabung dan alat sterilisasi casing. Jika ada persyaratan ketat mengenai kualitas jus, kedua sterilisasi ini dapat digunakan.

- Taizy memenuhi berbagai metode pengisian pelanggan, baik itu pengemasan, pengisian, atau pengisian botol, kami dapat memenuhi kebutuhan pengisian Anda.

Fitur mesin pengolah jus buah:

- Mesin pengolah jus buah memiliki struktur kompak, sistem kontrol lengkap, dan otomatisasi tingkat tinggi

- Cocokkan mesin yang berbeda sesuai dengan posisi produk yang berbeda untuk memenuhi kebutuhan pelanggan

- Banyak digunakan dalam pengolahan apel, mangga, anggur, pir, nanas, dan buah-buahan lainnya

- Kontrol penuh atas proses produksi, menghemat tenaga kerja, dan manajemen yang nyaman

- Sistem pengisian mengadopsi pengisian kuantitatif berkecepatan tinggi dan presisi tinggi untuk memastikan kualitas pengisian yang sangat baik.

- Semua mesin dan bagian yang bersentuhan dengan makanan di lini produksi jus terbuat dari baja tahan karat, yang tahan korosi dan mudah dibersihkan.